Yashwantrao Chavan Maharashtra Open University 2006 Certification TML Machine Design - Question Paper

Machine Design

TML073/EE/20070817

Machine Design

Time : 180 minutes Marks : 100

Instructions for the students :

1. All questions are compulsory.

2. "Long Answer type Question (LAQ)" is a supply type question of 20 marks, which require typical answer of about 60-80 lines in about 32-40 minutes.

3. "Short Answer type Question (SAQ)" is a supply type question of 5 marks, which require typical answer of about 15-20 lines in about 08-10 minutes.

4. Use of non-programmable type of scientific calculator is allowed.

5. Draw neat diagrams wherever necessary.

6. Assume suitable data if necessary.

Question (Q)

Question

Marks

Q-

No.

Long Answer type Questions (LAQ's)

(a) What is an importance of aesthetic considerations in the product design?

1

5

5

10

(b) What are the guidelines for the selection of different types of fits ?

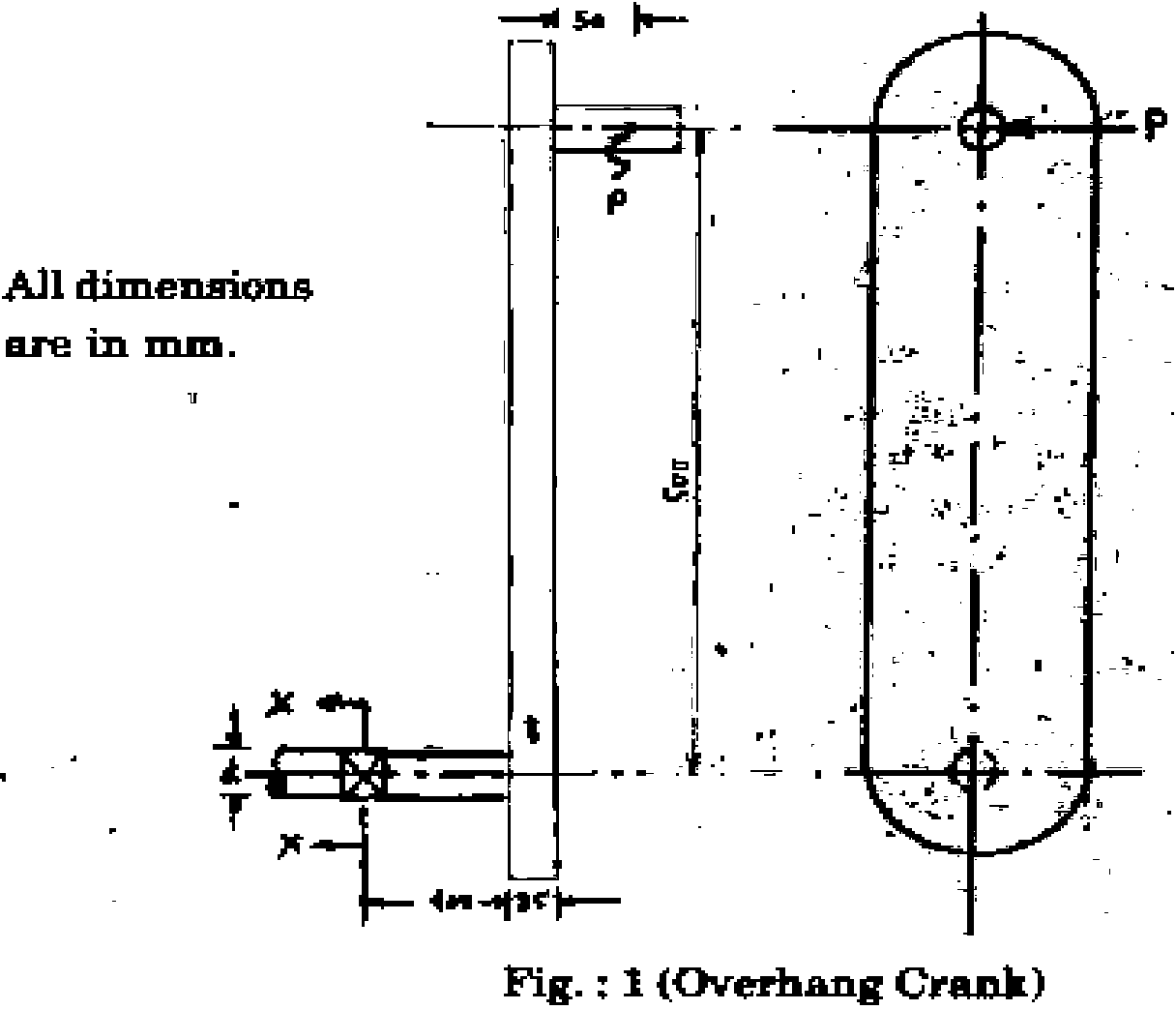

(c) The dimensions of an overhang crank are given in Figure 1. The force P acting at the crank pin is 1 kN. The crank is made of steel 30 C 8 (Syt = 400 N/mm2) and the factor of safety is 2. Using the maximum shear stress theory of failure, determine the diameter d at section XX.

|

2. |

(a) Define notch sensitivity. Explain its significance in design. |

5 |

|

(b) The work cycle of a mechanical component subjected to completely reversed bending stress consists of the following three elements : |

10 | |

|

i) 350 N/mm2 for 85% of time | ||

|

ii) 400 N/mm2 for 12% of time. | ||

|

iii) 500 N/mm2 for 3% of time | ||

|

The material for the component is 50 C 4(Sut = 660 N/mm2) and the corrected endurance strength of the component is 280 N/mm2. Determine the life of the component. | ||

|

(c) Explain the design procedure of the bolt subjected to eccentric loading when the load is parallel to the axis of the bolt. |

5 | |

|

3. |

(a) A solid circular shaft is subjected to bending moment of 3000 N-M and a torque of 10000 N-M. The shaft is made of 45 C 8 steel having an ultimate tensile stress of 700 mPa and an ultimate shear stress of 500 mPa. Assuming a factor of safety as 6, determine the diameter of the shaft. |

10 |

|

(b) Giving different types of spring combinations, derive load -deflection equation for Helical - compression spring. |

10 | |

|

4 |

(a) An automobile vehicle weighing 13.5 kN is moving on a level road at a speed of 95 km/hr. When brakes are applied, it is subjected to uniform deceleration of 6 m/s2. There are brakes on all four wheels. The tyre diameter is 750 mm. The kinetic energy of rotating parts is 10% of the kinetic energy of moving vehicle. The mass of each brake drum assembly is 15 kg and specific heat capacity is 460 J/kg0C. Calculate, i) Braking time ii) Braking distance iii) Total energy absorbed by each brake iv) Torque capacity of each brake v) Temperature rise in brake drum assemble. |

10 |

|

(b) The leather belt transmitting 15 kW power, between the pulleys rotating at 1440 rpm and 480 rpm respectively. The centre distance between the pulleys is twice the diameter of the big pulley. The belt should operate at a speed of 20 m/s approximately and the stresses in the belt should not exceed 2.25 N/mm2. The density of leather is 0.95 gm/cc and the coefficient of friction is 0.35. The thickness of the belt is 5 mm. Calculate : |

10 | |

|

i) The diameter of pulleys | ||

|

ii) The length and width of the belt | ||

|

iii) The belt tensions |

|

Short Answer type Questions (SAQ's) | ||

|

5. |

What is the factor of safety ? Why it is used in Machine Design ? |

5 |

|

6. |

What are the different types of threads ? State their advantages. |

5 |

|

7. |

Give in steps, with formulae, the design procedure of the pin of the flexible coupling. |

5 |

|

8. |

State the advantages and disadvantages of chain drives over belt and gear drives. |

5 |

N-93 TML073/EE/20070817:3

|

Attachment: |

| Earning: Approval pending. |