Maharashtra State Board of Technical Education 2008-4th Sem Diploma Mechanical Engineering Production Processes- - Question Paper

Sample Question Paper-I

Course : Mechanical Engg. Group Course Code: ME/PT/PG/MH Semester : Fourth Subject : Production Processes Max Marks : 80 Instructions:

1. All questions are compulsory.

9052

Time: 3 Hours

2. Figures to the right indicate full marks.

3. Use of non-programmable calculator is permissible.

4. Illustrate your answer with neat sketches wherever necessary.

5. Preferably, write the answers in sequential order.

Q1: A) Attempt Any Four Of the following. 08 Marks

a) What is dressing of grinding wheels?

b) Define following with reference to single point cutting tool

i) Side rake angle

ii) End clearance angle.

c) What is Part programming with reference to CNC lathe.

d) State the applications of deep hole drilling.

e) Name the process which will be used for the manufacturing of the following plastic items.

i) Plastic tubes iii) Plastic bottles

ii) Refrigerator inner panel. iv) Plastic jugs

Q1:B) Attempt any Two of the following. 08 Marks

a) The total length of part is 140 mm with tapered portion of 55 mm length.

Larger diameter of tapered portion is 30 mm and the smaller diameter is to be 20 mm. Determine the half taper angle.

b) State the use of following codes in part Programming.

i) G00 ii) G01 iii) M02 iv)M 05

c) Draw a neat-labeled, proportionate diagram of a twist drill.

Q.2: Attempt Any three of the following. 12 Marks

a) At what speed a 20 mm drill will run for cutting the steel at 25 m/min surface

speed. Determine the time required to drill the hole for a length of 30mm considering the approach and over travel of 2mm each with a feed of 0.2 mm/rev.

b) Explain with neat sketch T slot milling operation.

c) Differentiate between end milling & face milling operation.

d) Define canned cycle, How canned cycles are used in the part programs

Q.3: Attempt any three of following: 12 Marks

a) State the cutting parameters with reference to milling operations. What is their effect on machining time ?

b) State the principle of operation of gear hobbing with block diagram.

c) List down super finishing operations with applications of each of them.

d) Explain with a block diagram injection moulding process, state at least two components, which can be manufactured by injection moulding process.

Q4: Attempt any two of the following - 16 Marks

a) How the CNC machine differs from the conventional machine on the following points.

i) Machine structure

ii) Slide ways

iii) Motion transmission elements

iv) Drive units.

b) Describe with neat sketch gear shaping operation. State the advantages and limitations of the gear shaping process.

c) State the indexing methods used during gear cutting on milling machine and explain any one with practical application.

Q5: Attempt any two of the following. 12 Marks

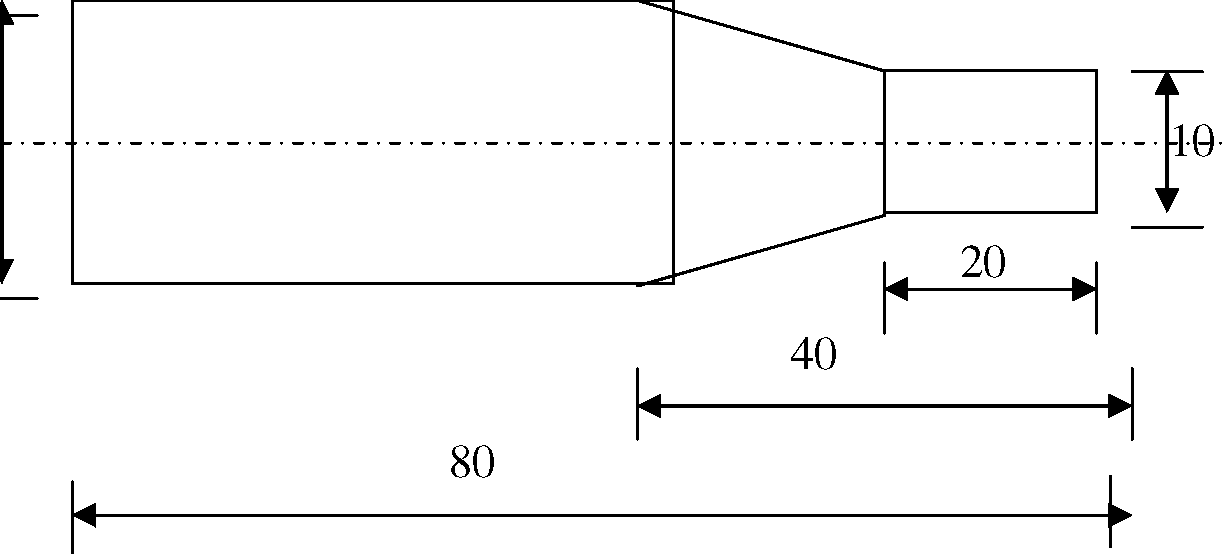

a) Prepare a program to machine work piece as shown in figure below on a CNC lathe.

|

50 |  |

b) What is the use of subroutine in part Programming? Explain a subroutine program with suitable example.

c) List down the components of grinding wheel with specific utility of each of these components in the manufacture of a grinding wheel.

Q.6: Attempt any two of the following. 12 Marks

a) With a skchematic diagram explain process of lapping. What is the difference between lapping and grinding ?

b) What are the different types of plastic? With a neat sketch explain vaccum forming.

c) Grinding wheel is designated as follows.

W A 46 K S V 17. Explain its meaning.

2

|

Attachment: |

| Earning: Approval pending. |