Thapar University 2006 B.Tech Chemical Engineering Fluidization engineering - Question Paper

Thapar Institute of Engineering & Technology

Chemical Engineering (4th Year)

Final Term exam

CH030 (Fluidization engineering)

9V

THAPAR INSTITUTE OF ENGINEERING AND TECHNOLOGY, PATIALA Department of Chemical Engineering

End-Semester Examination Fluidization Engineering (CH-030)

|

Semester -1, 2006-07 Max. Marks: 50 Answer all parts of the question at same place Assume suitable data, if required |

December 05. 2006 Tuesday 14.00-17.00 Hrs Faculty: Dr. D. Gangacharyulu |

|

1. |

a). Briefly write about the types of packings used in the packed beds and fluidization beds? |

5 |

|

b). Calculate the minimum velocity at which spherical particles, having specific gravity of 1.6. of diameter 1.5 mm will be fluidized by water in a tube of 10 mm The viscosity and density of water may be taken as 1.0 mN.s/m2 and 1000 kg/m3. The Kozenys constant is 5.0. The voidage may be taken as 0.48. If wall effect is considered, then what will be the minimum fluidization velocity? The wall effect is calculated as, fw = (1.0 + Sc/ S)2, Where. Sc is the ratio of surface area of the container and volume of the bed. where as S is the ratio of surface area of the particle and its volume. Take the unit height of the column for calculations. |

5 | |

|

2. |

a). Briefly write about the types of distributors used in the packed beds and fluidization beds? |

5 |

|

b). Cold particles of glass beads are fluidized with heated air in a bed in which a constant flow of particles is maintained. The gas flow rate is 0.2 kg/(m2-s), the specific heat of the air is 0.88 kJ/(kg-K), the viscosity of air is 0.015 mN.s/m2, the particle diameter is 0.25 mm and the thermal conductivity of the air is 0.03 W/(m-K). When steady state has been established, the temperatures recorded by a bare thermocouples immersed in the bed are as follows: I Distance above bed support (mm) i 0 I 0.64 1.27 I 1.91 ; 2.54 i 3.81 Temperature (K) i 339.5 i 337.7 ; 335.0 ! 333.6 ! 333.3 : 333.2 It may be expected that the area under the curve for above data as 8.82 mm K. Calculate the coefficient for heat transfer between the gas and particles, and the corresponding values of the particle Reynolds and Nusselt numbers. |

5 | |

|

3 |

a). Describe the applications of the fluidized bed technique with the help of neat sketch for: Process of Fluidized Bed Catalytic Cracking (FCC). and Process of Fluidized Bed Combustion (FBC) |

5 |

|

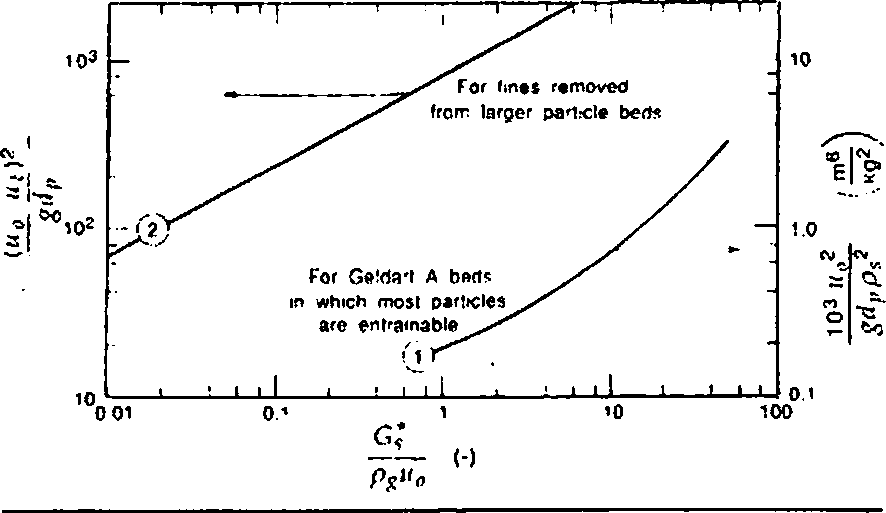

b). Calculate the rate of entrainment from a vessel fluidizing fine particles at high pressure. At the gas velocity used all the bed particles are entrainable, and the fluidized bed has a very high freeboard. The data of the problem is as follow: Average dp = 130 |im. ps = 1200 kg/m3, pg = 5.51 kg/m3, and u0 = 0.61 m/s. You may use the corresponding figure provided in Fig. 1. |

5 |

| |||||||||||||||

|

END |

|

|

FIGURE 1 Oimensionless plot for estimating the saturation carrying capacity G; ot a gas: curve 0 from Zenz and We<l (21]; curve (S> adapted from Gugnoni a>x) Zanz [8] |

|

Attachment: |

| Earning: Approval pending. |