Thapar University 2006 B.E Mechanical Engineering Machine Design-1 - Question Paper

Thapar Institute of Engineering & Technology

BE (2nd Year)

Final Term exam

ME006(Machine Design-1)

ME 006 MACHINE DESIGN -1 (2nd Year Mechanical Engineering)

Time: 3 Hours Max. Marks: 100

Attempt any FOUR problems.

Use of design data book is permissible. Give proper reference of data.

Assume the missing data suitably with proper reasoning.

Give the figures of arrangement andfinal design.

Use standard symbols only.

Attempt both parts at one place.

Dimensions, wherever shown, are in milimetre (mm).

A square thread power screw has a major diameter of 32 mm and a pitch of 4 mm with double

threads. The coefficient of friction = 0.08, dc- 40 mm, and r = 6.4kN per screw.

Determine

(a) the thread depth, thread width, mean or pitch diameter, minor diameter, and lead.

(b) the torque required to rotate the screwagainstthe load

(c) the torque required to rotate the screw with* the load

(d) the overall efficiency.

(25)

2.

(a) Discuss the design steps involvedetermining the size of double riveted butt joint subjected to eccentric loading.

(b) Two lengths of mild steel tie rods having w'idth 200 mm and thickness 12.5 mm are to be connected by means of a riveted joint wfith equal straps. Design the joint if the permissible working stresses are a, = %0MPa\r = SO MPa and ac = \ 50 MPa . Also determine the efficiency of the joint.

(10,15)

3.

(a) Explain clearly the need of theories of failure in design. Which theory would you recommend to be used for designing a component made of cast iron and subjected to combined bending and torsion load and why?

(b) A circular shaft is subjected to bending and twisting moments of 10 kN.m and 30 kN.tn respectively. Design the shaft and key using maximum shear stress theory and considering the effect of keyway. The material of shaft and key is plain carbon steel (- 400 MPa; S>T-260Mpa).

(10,15)

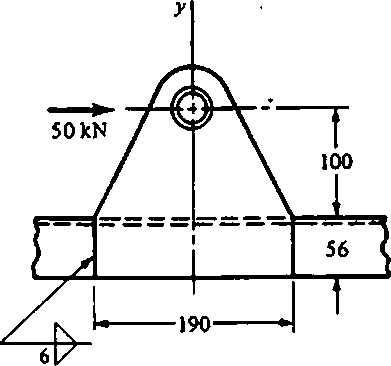

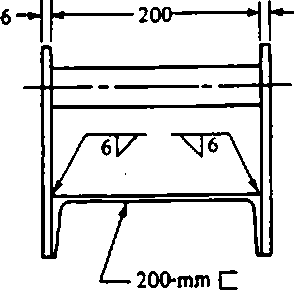

4. A 50 kN load is transferred from a welded fitting into a 200 mm steel channel as shown in Figure

1. Compute the maximum stress in the weld.

(25)

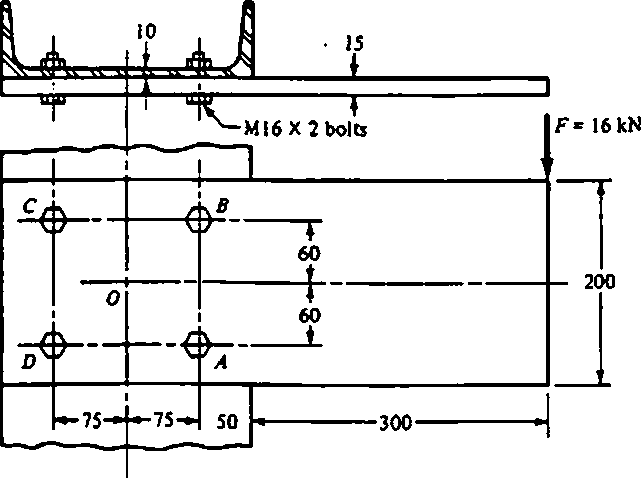

5. A 15 x 200 mm rectangular steel bar is cantilevered to 250 mm steel channel using 4 bolts as

shown in Figure 2. On the basis of the external load of 16 kN. Determine

(a) the resultant load on each bolt

(b) the maximum bolt shear stress

(c) the maximum bearing stress

(d) the critical bending stress in the bar.

25 kN

100

no.4

Diagram showing the weld geom-sty; all dimensions in millimeters.

Note that V and M represent loads applied by the welds to the plate.

|

t y 45.6 | ||||||||||||||||

|

95- | |||||||||||||||||

T

56

1

fiO,. 1

|

Attachment: |

| Earning: Approval pending. |